Specification

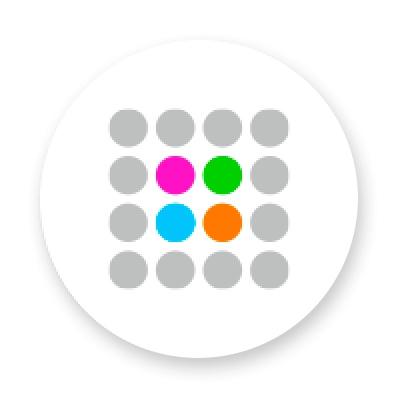

This tool consists of 5 printed pages. The reference page is labeled as the Master page. The other four pages are marked as Level A, Level B, Level C and Level D. Pictures printed on those pages represent color deviation to the reference page specified by each level:

Level A ∆E < 2

Level B ∆E < 3

Level C ∆E < 4.5

Level D ∆E < 6

All listed values represent quality Levels specified by CGATS21 TR016

For all calculations, ∆E 2000 formula is used.

Pictures are calculated pixel by pixel to find the exact value of ∆E but in some cases requested color shift can exceed the gamut of a printing device. The printing process can cause some inaccuracy for a limited part of the pixel reproduction. The goal is to achieve an accuracy of 0.5> ∆E for 90% of pixels. For each production batch, measurements of all flat colors located on the vertical edges of each page are made and performed via statistical analysis.

Also, pixel-by-pixel analysis of source files was made for all critical combinations.

Executive overview

The Chromachecker Color Tolerance Exercise is designed to be a fast, simple, accurate way to correlate a person's ability to visually judge an acceptable color match with a standard, known, numeric standard to determine color difference called Delta ∆E2000. This exercise is process agnostic; it relates to Large Format, Digital Printing, Flexography, Conventional Sheetfed, and Web offset printing processes.

Today a Print Organization has two main ways to differentiate themselves from competitors, first- by Price (meaning commodity product) or Secondly by Quality- but how do you quantify QUALITY? Now with TR016 (Technical Reference) referred to in CGATS21, Print Organizations have the ability to differentiate themselves based on Quality! If you want to perform work for demanding customers that request an audit, or prints to prove a printer's precision and accuracy, then this exercise is required to educate your customers about color difference and why your company can ask for a premium price because your precision and accuracy is better then other, lower quality, (commodity) print organizations.

It is designed to be a stand-alone exercise, capable of being taken by an individual, department, or company at any time. The person taking the exercise does not have to know anything about color except knowing what is an acceptable match for them, or when used with a group when the group decides based on consensus.

This exercise is designed for any company involved in reproducing color. It is required for any company looking to implement process control procedures, calibration, and or Color Profiling tools. Everybody has a different view of what is an acceptable color match. Up until now, it has been very hard to quantify this value. The only real way to determine what a person's tolerance was a lot of trial and error experiences, which can be frustrating and lead to unattainable expectations, and if multiple people are involved, inconsistent results.

Part of CGATS21 References TR 016 for Printing Tolerancing and Conformance Assessment. This Document references four levels of Color Tolerancing as a way to differentiate a company's business by qualifying color quality.

This Exercise will allow the user to:

- Determine a Company-wide standard for the level of color tolerance

- Armed with this value, the company can easily determine:

- How long it take certain color devices to drift beyond your Tolerance, Which allows your organization to determine the maintenance schedule for each device

- Qualify that the quality and repeatability of devices like Color Measurement devices, Scanners, Monitors, and Output devices fall within acceptable tolerance standards based on the Tolerance value determined.

- Qualify your customer's tolerance to determine how particular they are before you provide any services for them because it will allow you to quote the job out more effectively. For instance, you might be able to provide less expensive proof if the customer tolerance is a higher number.

We truly believe that in a very short time, companies will charge their customers based on how tight of color tolerance the customer requires.

Technical background: The test uses the ∆E 2000 formula for all calculations. The differences are subject to differences in hue, lightness, and saturation.

Custom Tolerance exercises can be customized by us for just about any color or purpose, e-mail david@pilotmarketing.com for more information.

Any questions about this exercise can be forwarded to David Hunter at david@chromachecker.com. This exercise is copyrighted by Pilot Marketing in 1999, 2000, and 2001, and by ChromaChecker in 2014-2022.

We offer the Yellow and Blue Edition of this tool

The substrate is the fifth color in four-color printing. Depending upon the print application, blue or yellow paper is very common. By building the Tolerance exercise with yellow paper simulation and blue paper simulation you can provide the effect of the color of the substrate in terms of changing the appearance of the page.

Color deviations in the Yellow Edition are made by increasing both L* and b* and the constant value of a*. The results are that every picture becomes more yellow and darker.

For Blue Edition, L* is increased but b* is decreased while keeping the a* value constant – result: pictures become blueish and darker. Printed samples help to learn what is a range of color deviation for all Quality Levels described in CGATS21 TR016.