Color Quality Control

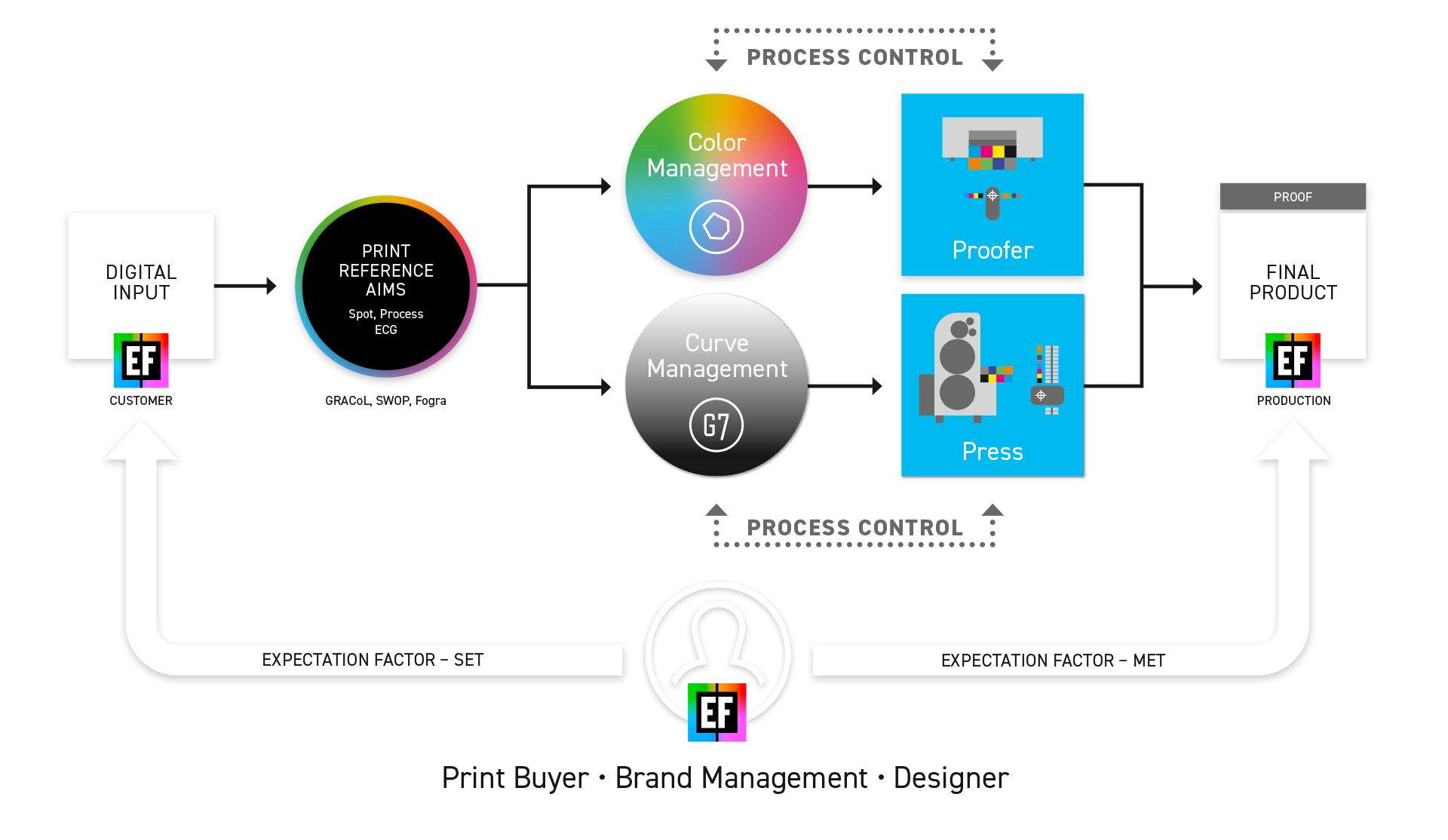

Color Quality Control or Color Conformance is based on first establishing organizational goals and providing a method throughout the organization for the communication of those goals. Tolerances are set based on Delta E for spot colors as well "E-Factor" which is a formula based on Delta E evaluating overall pages and process color. ChromaChecker will also monitor process control compliance such as G7 and key production variables such as ink density, TVI, plus patterns along with color influences such as substrate white point, material texture, lighting, and temperature/humidity all to provide guidance alerting operators and management when quality check tolerance is not met. Reporting is provided to quantify both the quality and productivity of the production environment.

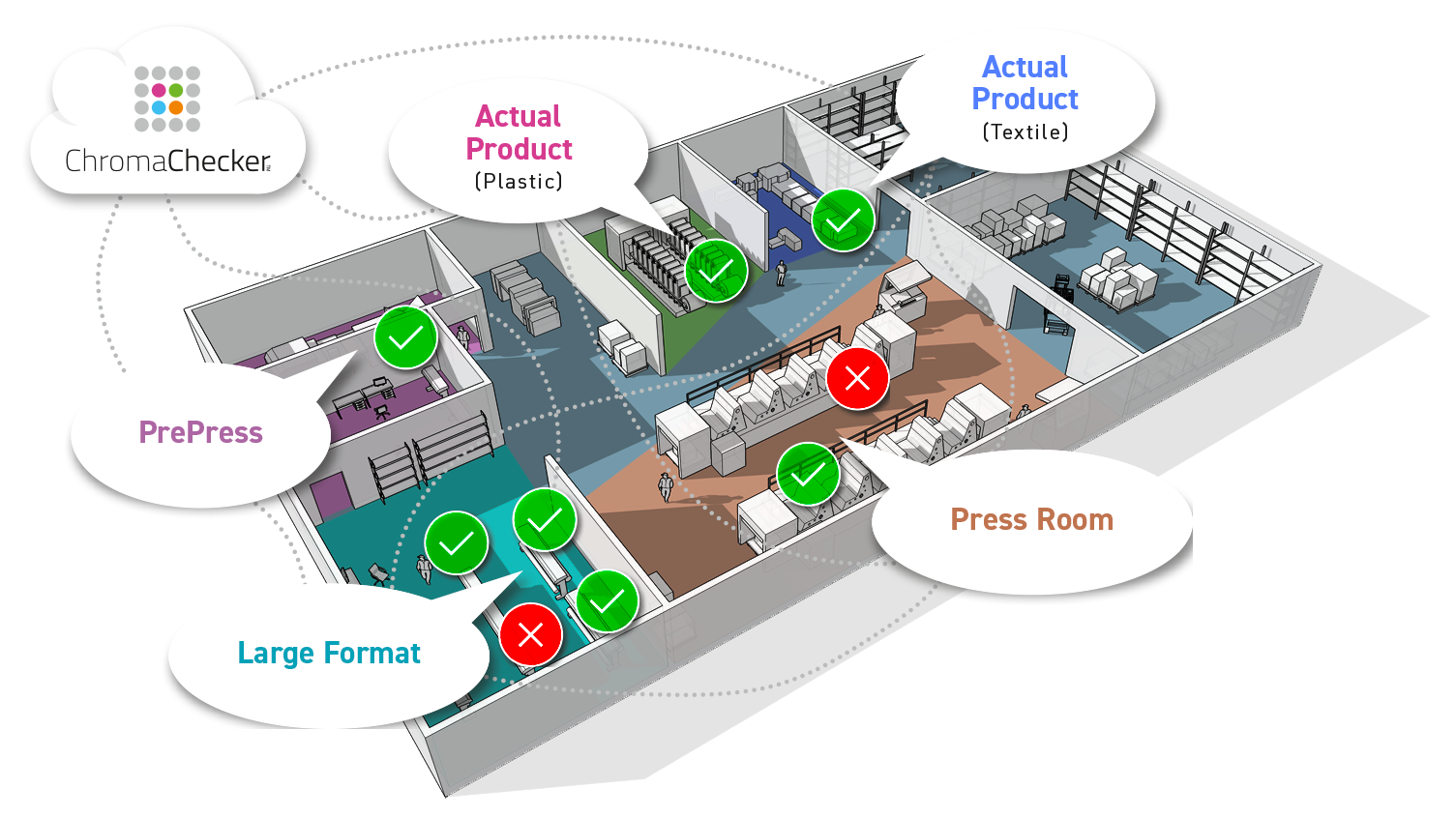

Chromachecker allows an organization to support a quality program that empowers the entire organization by communicating a number with a Green/Red indication for determining if the consistency of the printing process is within tolerances set by the market requirements and capabilities of the devices in use. So the implementation of a quality program depends on a few ingredients in an organization including:

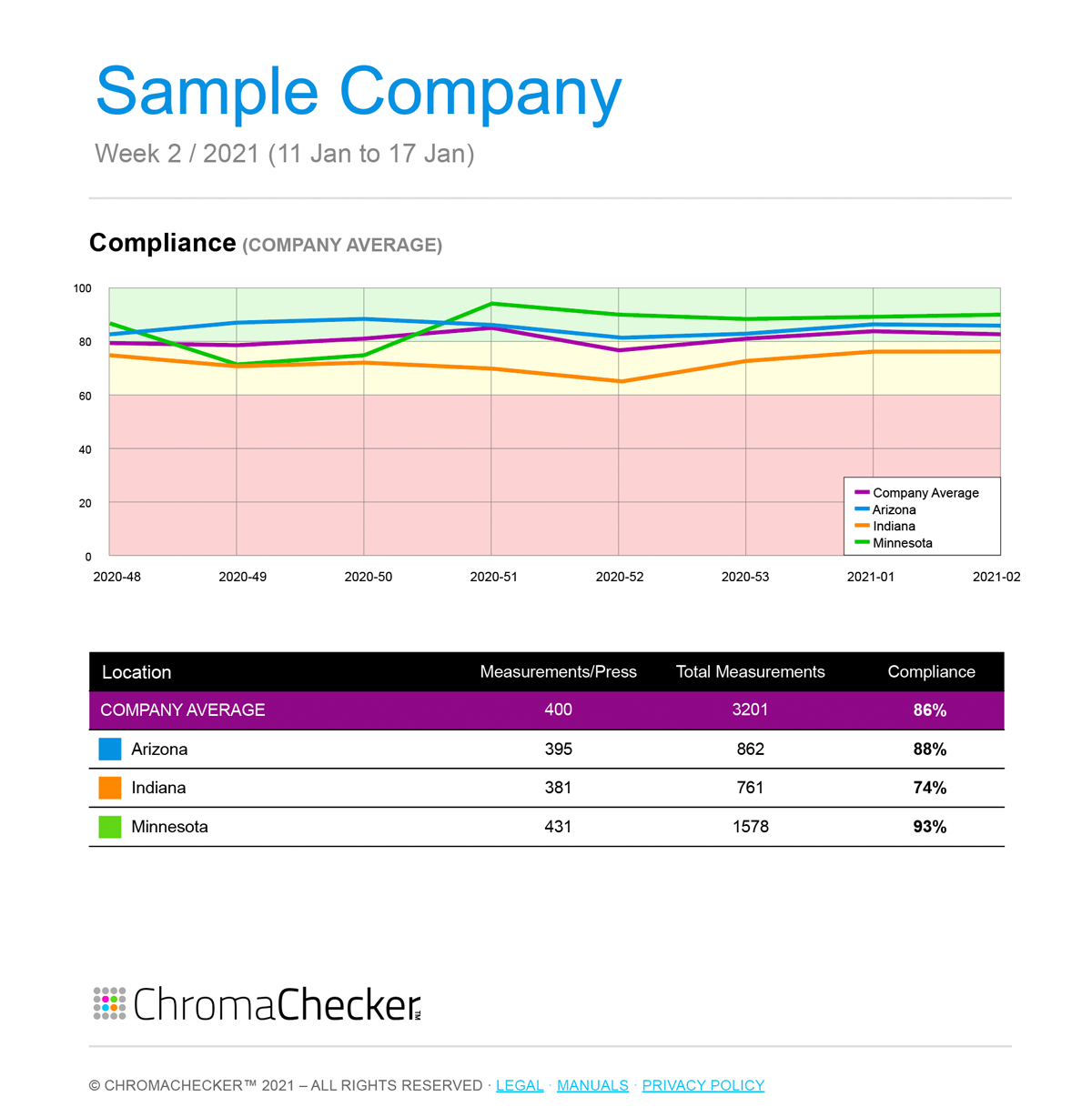

- Leadership Involvement - Key Performance Indicator reports (KPI) providing a window to the quality control progress and providing management a consolidated view to pinpoint decision making.

- Vision - Knowing where the organization is going regarding quality and how it enables efficiency and productivity.

- Roadmap - Defining the overall goal or the organization and detailing the pathway for success.

It’s worth highlighting that ChromaChecker enables improved efficiency by providing operators when to perform maintenance tasks by pinpointing errors in the production process. ChromaChecker identifies what maintenance is required as it relates to outcomes rather than the common approach of performing random maintenance that may not be necessary. This allows for a manufacturing approach to keep production running while stopping when the output will be determined as waste.

ChromaChecker is unique in that it implements measurement tasks that compliment the production process, defines procedures for resolving anomalies, and empowers an escalation process through centralized real-time communication. ChromaChecker is built to complement the production process and guides the operator if compliance is not met. Operators can solve the most common errors proactively. Issues are only escalated to Management and Experts when more complex errors occur. As an example, Operators are alerted to the substrate being incorrect while device malfunctions can be escalated to Management and Experts for diagnosis and resolution. The information is centralized for easy access to data for analysis.

![]()

Color Conformance Platform

![]()

With this infrastructure in place, leadership can direct the organization to establish the KPI reporting that defines the “Current State” of the organization’s color capabilities as it relates to accuracy and consistency. This provides the capabilities as well as the limitations of the current infrastructure including identifying gaps with equipment infrastructure such as instrumentation, printing devices, along with manufacturing processes, materials, environmental condition,

Once the current state or window to production is established, a roadmap will define how any gaps will be eliminated. This becomes the basis for realizing the full potential of past investments while defining the methods for evaluating future investments. Ensuring that the true cost of ownership of equipment is established by defining the supply and maintenance costs required to meet accuracy and consistency requirements set for the organization.

Place Holder Image Showing Capture - Latest Version

Video

-

The tutorial shows how to connect the xRite ICPlate to ChromaChcker Capture - Follow the instructions in Capture to create a baseline creation and providing a Quick Audit. 20, 40, 60, 80% and example Fast Verification.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.