Precision vs. Accuracy

|

|

|

|

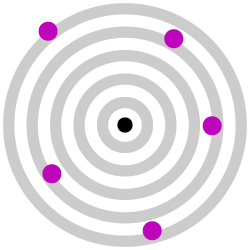

| LOW ACCURACY LOW PRECISION |

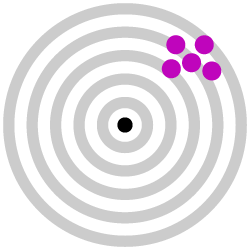

LOW ACCURACY HIGH PRECISION |

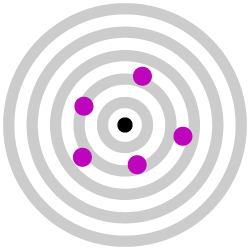

HIGH ACCURACY LOW PRECISION |

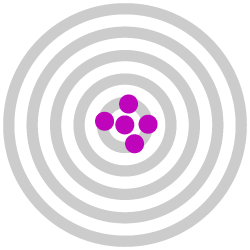

HIGH ACCURACY HIGH PRECISION |

Precision defines the consistency of a device (printer, measurement device, light booth, and more)

Accuracy defines how close the device (printer, measurement device, light booth, more) matches the reference, OR another device (printer, measurement device, light booth, more).

Both precision and accuracy are required for top-level color control. ChromaChecker assesses both precision (compared to baseline, and automatic comparison of identical patches) and accuracy (compared to the reference, or compare to another printer) on every measurement, unlike any other system on the market. It can also assess the precision of the paper if the user configures Substrate Inspector.

More details

Every print device natively prints differently from one another even with the same make and model. When attempting to make multiple printing devices (digital, large format, flexography, sheetfed) match one another, it is imperative to ensure each device is consistent to itself, and that it is matching an industry reference print condition (which allows them to match one another). This requires both precision and accuracy.

Precision and accuracy are often confused and interchanged when talking about color control, but they are very different and need to be treated independently of one another. Precision should be determined before accuracy. Precision defines how repeatable a process is, not only within a page (intra-page variation) but also across multiple printed pages within the same job (inter-page variation or repeatability) and between different jobs (reproducibility). Precision is controlled by calibrating and linearizing the printing process, each process has its own procedure and is very device-specific.

The ChromaChecker™ Print Inspector will calculate all levels of the precision of your device based on the measurement results from the control strips. Precision also defines how repeatable a process is over time, between jobs, and between maintenance, to ensure a device is always coming back to its known and consistent state within an allowable tolerance defined in delta E that you should have already defined by using the ChromaChecker™ E-Factor Exercise. This tolerance ensures the device is repeatable within a given amount of "color difference" which is determined to be acceptable by the owner of that device. Understand that the paper or substrate that a device is printing on is considered the 5th color in four-color printing and will greatly influence the color of the result. Often multiple substrates are used with the same device, which will influence the amount of color variation resulting from the print. Depending upon the desired tolerance required, you may need to profile groups of substrates that have similar color characteristics (within a given tolerance) to allow for the extreme differences that paper can have on your final color result. The ChromaChecker Print Inspector will calculate this for you based on your device/substrate characteristics.

Once the precision of a device/paper of a device is determined, then the ability to make that device/paper condition match an industry reference condition will be important. Matching a "reference" condition determines the "accuracy" of a device condition. By matching an industry reference condition, multiple devices within the same company can match one another, and multiple devices across the world can match one another within a given color tolerance, and be deemed acceptable (Pass) or unacceptable (Fail). Accuracy is achieved by applying G7 curves, or ICC profiles in the workflow in order to adjust how each printing device needs to print in order to match the given reference condition. ChromaChecker can create both the G7 Curve and or the ICC Profile for the given print condition to help direct it to better match the desired reference condition.

The ChromaChecker Print Inspector will calculate which reference color space including your own imported color spaces are the closest match to your device/substrate characteristics for properly configuring your color conversion workflow, and how to assess the results.

Practical solutions

- ChromaChecker developed test forms and Control Strips dedicated to such evaluation.

- The CC Capture QuickChecke offers a "Start Variation" with an instant Precision and Accuracy analysis

- That kind of methodology is applied in all ChromaChecker Printer's Benchmarking Procedures.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.