Substrate Inspector

ChromaChecker™ Substrate Inspector provides analyzing, and tracking all details that affect how the human eye perceives differences in substrates used in the Printing Industry. By creating a Substrate Library you can track changes in substrate over time and most importantly troubleshoot changes in the substrate during quality control checks during production. By tracking substrates during production ensures that changes in substrate do not cause an unacceptable color shift in the print production process. Substrate Inspector also allows printers to hold their suppliers accountable to ensure the substrate meets the production specifications at all times.

What do you need?

1. A supported Spectrophotometer:

- X-Rite i1Pro 2 / X-Rite i1Pro 3

- X-Rite eXact

- Techkon SpectroDens

- X-Rite i1iO

- Nix

- Spectro 1/ Spectro (limited functionality)

2. CC BW Backing

When measuring substrates, it is critical to measure the substrate with both white and black backing underneath the substrate. The white and black needs to meet industry standards: ISO 13655 for White and ISO 5 for Black Backing. The user may alternatively use 11x17"CC Measurement Backing.

3. CC Capture

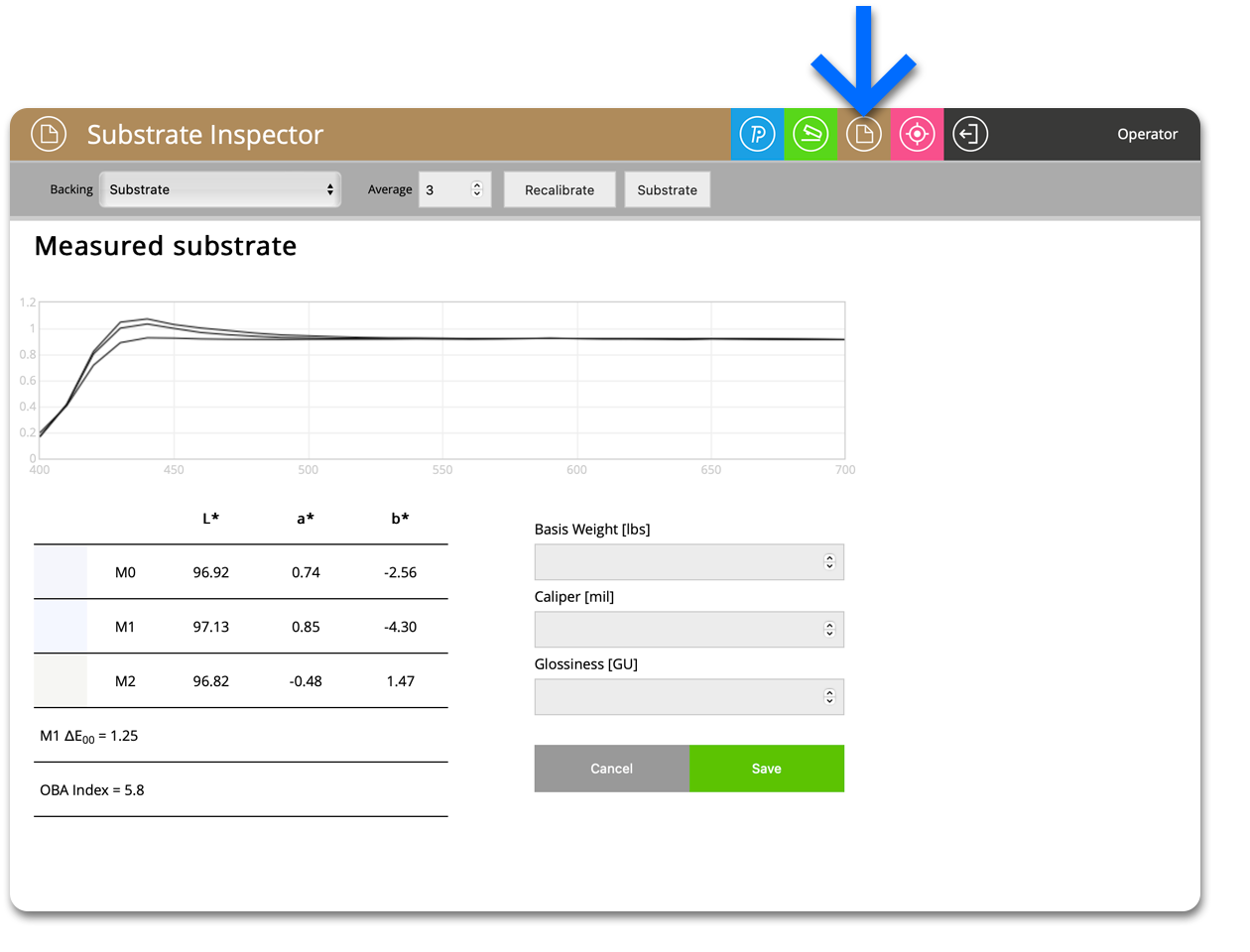

An example of basic measurement (on white backing only). There M-condition curves and Lab coordinates M1 ∆E 00 difference from reference and OBA Index.

To run CC Capture, an Operator's credentials are required. During the registration process, at least one account (Default Operator) has been created, but due to accountability management, it makes sense to create additional operators accounts.

Additional hardware

More accurate substrate variables can be tracked with additional measurement devices including:

|

|

|

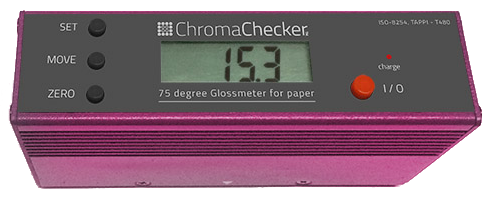

| Gauge Meter | 75° TAPPI Glossmeter | Scale |

| Quickly measure thickness, can be alternatively made with a micrometer or caliper. | Standard: ISO 8254/1, TAPPI T480 specifies geometry for substrate measurements | Any scale can be used for evaluating Basis Height/Grammage. |

Additional methods for substrate tracking offered by the ChromaChecker

When using an inline measurement device such as an ILS instrument inside an Epson or HP type printer, then the measurement itself can be used to define a baseline to define how that instrument measures the specific substrate for tracking consistency over time for the given automated measurement device.

Using Color Inspector and CC Nano allows additional surface parameters to be tracked, such as how well the printed white is covering the substrate that is being used in manufacturing.

Video

-

This tutorial shows you how an operator can create a Substrate Library. Substrate is the 5th color in printing so ensuring consistent substrate properties is one of the key areas for ensuring consistent results.

-

This tutorial covers Substrate inspector, Measure Press Paper baseline, Apply to Track, and shows how imported data shows how the substrate is tracked independently of press measurements

-

Use Substrate inspector and find a closer proofing paper to press paper for the closest match! Find the closest match and re-profile proofer to match press

Related Topics

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.