|

|

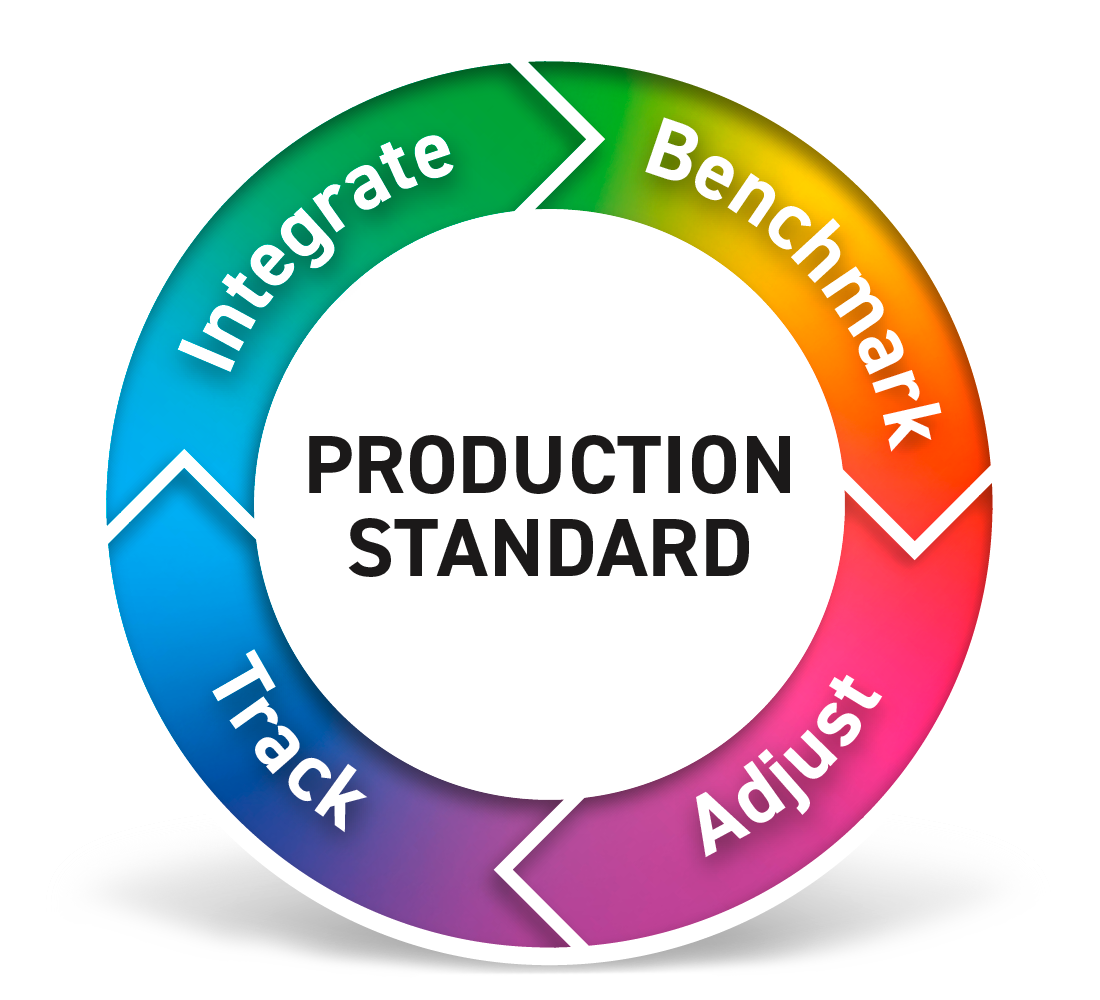

ChromaChecker – 5 steps to Color Conformance

|

1. Standard |

2. Benchmark |

3. Adjust |

4. Track |

5. Integrate |

|

|

|

|

|

Top designers know that awareness and participation in the print and manufacturing process are critical for a smooth transition from creativity to production. What you envision during the creative process needs to be reproducible especially if budgeting is important. Communication between the design phase and print production phase helps to eliminate the most common difficulties proactively. It’s safe to say that the creative processes start today at the monitor with a dependency on the material used for the final product. The approval process will work its way to a production environment that has inherent limitations that will impact both quality and cost. ChromaChecker brings color communication to the design level with functionality that allows for communicating color using a Virtual Print engine that is aligned directly with the profiling in production. Designers are able to manage Color Libraries in ChromaChecker and provide centralized sharing of color definitions using CxF4 formatting, testing the print profiling process, and receiving feedback regarding the potential shift in color during printing or manufacturing of products. ChromaChecker also provides the ability to read any surface to receive color specifications for analysis at the product level. This start to finish analysis provides the designer with confidence and insight into the represented color and how it will be reproduced.

For whom?

- Graphic Designer - especially working with Adobe Photoshop, Illustrator, InDesign... - for upgrading to top-professional level, including advanced soft- and hard-proofing, color libraries, and data exchange...

- Industrial Designer - when dealing with textiles, paints, plastic, or printed colors

- Interior Designer and Architects - for creating color libraries and creates

- Light Designers and Engineers - for light measurements

- Photographers - to get control of the Display and Printer, check lighting conditions and understand color better.

Designer CC Toolbox:

- Color Inspector - creating color palettes, tracking color differences, exporting libraries to Adobe Apps

- Substrate Inspector - creating libraries of substrates

- Lighting Inspector - analyzing Lighting Conditions

- Display Inspector - calibrating, profiling a verification of the Displays,

- Print Inspector checking the quality of prints, creating printer ICC profiles,

- ICC Profile Inspector - comparing ICC Profiles

Key Benefits

- The user may be a professional partner for high demanding customers ready to exchange advanced data

- System imports and exports a lot of industrial data formats including CxF, CGTAS formats for color definition (references and measurements)

- The workstation can be certified as a soft-proofing, hard-proofing station.

- The User can share professional data with others.

- We offer a super-low-cost solution for hard-proofing.

- Learn and improve your skill in quantifying color differences based on E-Factor Exercises, Spot Color Exercise, and Image Color Exercise.

Learn more about how easy is to:

- Create a professional Color Library based on spectral data

- Amazing low-cost instruments for color measurements

- Learn your system limitations - check what you can print and what you can display,

- Calibrate and profile your monitor.

- Turn your low-cost color printer into the profiled, predictable color output device. Find substrates that can extend the gamut and better cover needs.

- Follow the step by step procedure how to turn a regular ink-jet printer into a hard-proofing station and create certified proofs

- Learn about how e-Factor Exercise/Sampler can help you with color communication with the customer

- Understand basics of Color and Color Management with CC